Modern glass production and processing factory with intelligent management has given rise to an urgent demand for a more efficient storage and handling systems. In a glass factory, the glass handling to storage can be managed fully automatically by production database requirements.

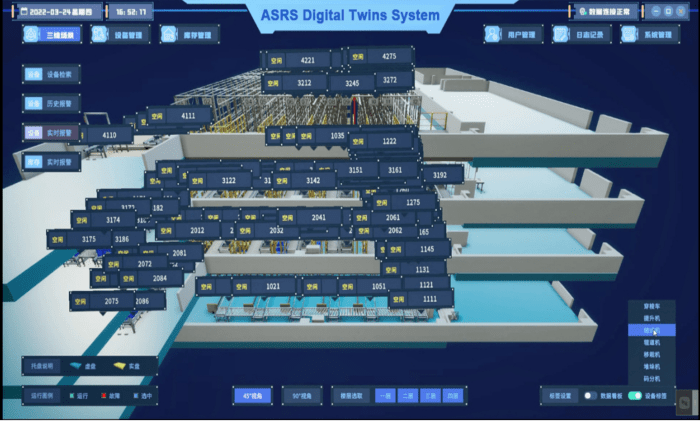

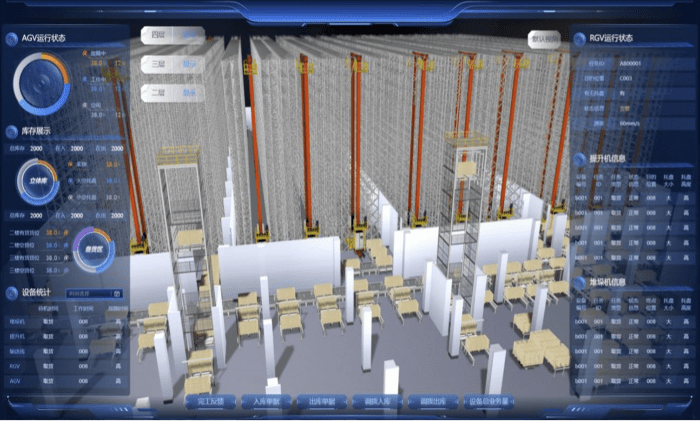

ASRS is an automated warehousing and logistics system. It uses automated equipment to manage inventory information, achieving automated out-warehousing, in-warehousing, and handling of glass and other materials.

Right now the full ASRS system has been widely used in the solar glass and PV panels production factory. It is integrated with the whole factory automatic production system and intelligent database. MAC has helped several big groups focusing on solar energy development to achieve full automatic storage and in-factory logistics. When the goods weight between 2-5 tons/pcs, ASRS will always give the perfect solutions.

1. Cost and Safety

ASRS remove most of labor in the storage and logistics area. It dramatically reduce the labor injury in the glass industry, at the same time save cost. The logistics cost is also saved at clear and easy calculation.

2. Efficiency

ASRS has a much higher in-warehouse and out-warehouse speed. In addition, the management efficiency is much more upgraded.

Fully and efficiently utilize three-dimensional space. It rise the factory space efficiency

3. Upgraded service

The accurate storage and access of glass and other material according to production process brings excellent organization to avoid mistake and damage.

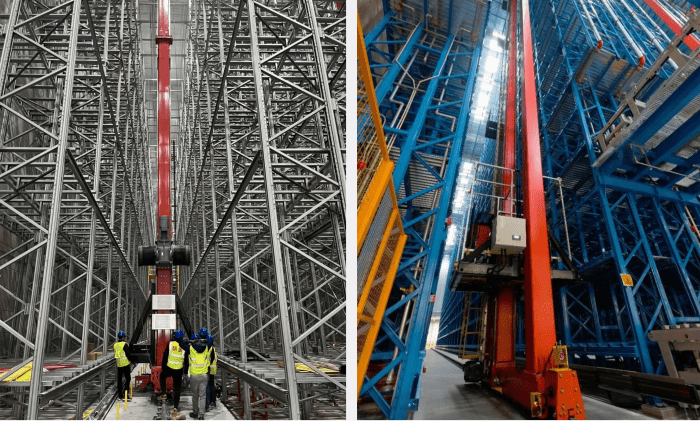

A full ASRS system consists of storage racks, stacker cranes, conveyor system, AGV/RGV, WCS control system and WMS intelligent management system.

TASHKENT--(Press Release)--MAC Technology, an innovative leader in glass processing automation, is pleased to announce its participation in the prestigious UzGlass Expo 2025. The exhibition will be held November 26-28, 2025 at the Tashkent Expo Cent...

ISTANBUL--(Press Release)--MAC Technology, an innovative leader in glass processing automation, is pleased to announce its participation in the prestigious Glass Tech Turkey 2025. The exhibition will be held November 15-18, 2025 at the Istanbul Expo...

JAKARTA--(Press Release)--MAC Technology, an innovative leader in glass processing automation, is pleased to announce its participation in the prestigious Asia Glass Indonesia 2025. Taking place November 6-9, 2025 at Jakarta International Expo, we w...

[USA] – MAC Technology, a global leader in advanced glass processing automation, is proud to announce its participation in the premier GlassBuild America 2025. The event will be held from November 4-6, 2025, and we warmly welcome all current ...

Category

Copyright © 2026 China MAC GLASTECH AND AUTOMATION CO.,LIMITED. All rights reserved — Privacy Policy