Understanding Modern Glass Drilling Technology and Safety Mechanisms

The world of glass fabrication has evolved significantly with the introduction of advanced glass drilling machines that can handle various glass thicknesses with remarkable precision. These sophisticated pieces of equipment combine cutting-edge technology with robust safety features to ensure flawless results while protecting both operators and materials. Modern glass drilling machines incorporate sensors, automated controls, and specialized drilling components that work in harmony to process different glass types and thicknesses efficiently.

The capability of glass drilling machines to adapt to different glass thicknesses represents a significant advancement in glass processing technology. These machines utilize precise calibration systems and intelligent pressure control mechanisms to prevent glass breakage while maintaining optimal drilling speeds. Understanding how these machines operate is crucial for manufacturers, fabricators, and industry professionals who work with glass materials daily.

Core Components of Professional Glass Drilling Systems

Advanced Drilling Mechanisms and Controls

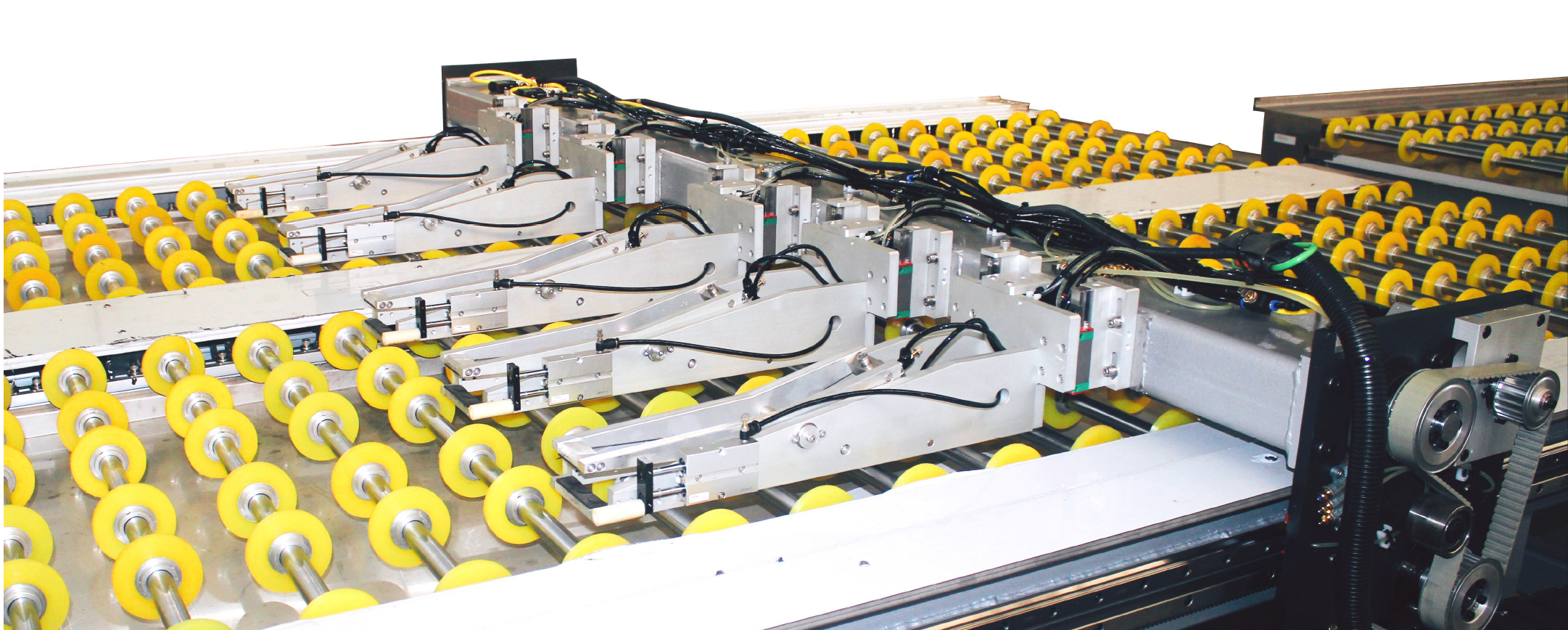

At the heart of modern glass drilling machines lies a sophisticated drilling mechanism that combines variable speed control with precision positioning systems. The drilling head features diamond-tipped bits specifically designed for glass applications, while the control system continuously monitors and adjusts drilling parameters based on glass thickness and composition. These machines employ servo motors and linear guides to ensure smooth, vibration-free operation during the drilling process.

The control interface allows operators to input specific glass parameters and automatically adjusts drilling speed, pressure, and cooling requirements. This level of automation significantly reduces the risk of operator error while maintaining consistent quality across multiple drilling operations.

Cooling and Lubrication Systems

Glass drilling machines incorporate advanced cooling systems that are essential for maintaining optimal drilling conditions. The cooling mechanism typically uses a precise mixture of water and specialized coolants to prevent overheating at the drilling point. This system adjusts the flow rate and pressure based on the glass thickness being processed, ensuring proper temperature control throughout the operation.

The lubrication system works in tandem with the cooling mechanism to reduce friction and prevent chip accumulation. This integrated approach helps extend tool life while maintaining superior hole quality across different glass thicknesses.

Safety Features and Thickness Detection Technology

Automated Thickness Recognition Systems

Modern glass drilling machines feature sophisticated thickness detection systems that automatically measure and verify glass dimensions before processing begins. These systems employ laser sensors or mechanical probes to accurately determine glass thickness and adjust drilling parameters accordingly. This technology prevents operator mistakes and ensures that the appropriate drilling specifications are always used.

The thickness recognition system communicates directly with the machine's central control unit, automatically updating speed, feed rate, and pressure settings to match the specific requirements of each glass panel. This intelligent adaptation capability significantly reduces the risk of glass breakage and ensures consistent quality across varying thickness ranges.

Emergency Response and Protection Mechanisms

Safety is paramount in glass drilling operations, and modern machines incorporate multiple layers of protection. Emergency stop systems can instantly halt operations if abnormal conditions are detected, while protective enclosures prevent glass chips and debris from causing injury. These machines also feature pressure monitoring systems that can detect potential stress points before they lead to glass breakage.

Advanced glass drilling machines include backup safety systems and redundant controls to ensure continuous protection even if primary systems fail. This comprehensive approach to safety helps maintain a secure working environment while processing different glass thicknesses.

Processing Capabilities and Applications

Range of Glass Thickness Handling

Glass drilling machines are designed to accommodate a wide range of glass thicknesses, typically from 3mm to 19mm or more, depending on the model and specifications. These machines can process various glass types, including tempered, laminated, and decorative glass, with equal precision and safety. The ability to handle multiple thickness ranges makes these machines versatile tools for diverse manufacturing applications.

The processing capabilities extend beyond simple through-holes to include countersunk holes, shaped openings, and multiple hole patterns. This versatility allows manufacturers to meet various architectural and industrial requirements while maintaining strict quality standards.

Industry-Specific Applications

Glass drilling machines serve numerous industries, from architectural glass fabrication to automotive manufacturing. In architectural applications, these machines create precise holes for mounting hardware, balustrades, and structural glass elements. The automotive industry relies on glass drilling machines for creating holes in windshields and side windows for various attachments and sensors.

The flexibility of modern glass drilling machines allows them to adapt to specialized applications in the furniture industry, electronics manufacturing, and custom glass fabrication. Each application benefits from the machine's ability to handle different glass thicknesses safely and efficiently.

Maintenance and Optimization Practices

Regular Calibration and Testing

Maintaining optimal performance of glass drilling machines requires regular calibration and testing procedures. Operators should perform daily checks of critical components, including drilling bits, cooling systems, and safety mechanisms. Regular calibration ensures that thickness detection systems remain accurate and that drilling parameters are optimized for different glass types.

Implementing a structured maintenance schedule helps prevent unexpected downtime and ensures consistent drilling quality. This includes regular inspection of wear components, cleaning of cooling systems, and verification of safety feature functionality.

Performance Monitoring and Adjustment

Modern glass drilling machines include sophisticated monitoring systems that track performance metrics and alert operators to potential issues. These systems collect data on drilling speeds, pressure levels, and coolant flow rates, allowing for continuous optimization of drilling parameters. Regular analysis of this data helps identify trends and potential areas for improvement in the drilling process.

Advanced monitoring capabilities also enable predictive maintenance, helping operators schedule service interventions before problems occur. This proactive approach to maintenance helps maximize machine uptime and ensure consistent quality across all glass thicknesses.

Frequently Asked Questions

What is the maximum glass thickness that can be safely drilled?

Most professional glass drilling machines can safely handle glass thicknesses ranging from 3mm to 19mm, though some specialized machines can accommodate even thicker glass. The maximum safe thickness depends on the specific machine model, drilling bit type, and glass composition. Always consult the manufacturer's specifications for exact capabilities.

How does the cooling system prevent glass breakage during drilling?

The cooling system delivers a precise mixture of water and coolant directly to the drilling point, maintaining optimal temperature and preventing thermal stress. The system automatically adjusts flow rates based on glass thickness and drilling speed, ensuring consistent cooling throughout the process while preventing thermal shock that could lead to breakage.

What maintenance is required to ensure safe operation across different glass thicknesses?

Regular maintenance should include daily cleaning of cooling systems, inspection of drilling bits for wear, calibration of thickness detection sensors, and testing of safety mechanisms. Additionally, operators should verify the accuracy of pressure controls and monitor coolant quality. Following the manufacturer's maintenance schedule and keeping detailed service records is essential for safe, reliable operation.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

GA

GA

AZ

AZ