Seamless Integration of Modern Glass Sorting Technologies

The integration of a glass sorting system into existing production lines represents a significant advancement in glass manufacturing and recycling operations. These sophisticated systems utilize cutting-edge technology to streamline the sorting process, enhance quality control, and maximize operational efficiency. Understanding how these systems work in harmony with other glass processing equipment is crucial for facility managers and operations specialists looking to optimize their production capabilities.

Modern glass sorting systems have revolutionized the way facilities handle various types of glass materials. From cullet processing to final quality inspection, these systems serve as the backbone of efficient glass handling operations. Their ability to seamlessly connect with existing infrastructure while providing precise sorting capabilities makes them an invaluable asset in any glass processing facility.

Core Components of Integrated Glass Processing

Material Handling and Conveyor Systems

The foundation of any successful glass sorting system integration begins with robust material handling equipment. Specialized conveyor systems are designed to transport glass materials efficiently while minimizing breakage and contamination. These systems must be carefully calibrated to maintain consistent flow rates and prevent bottlenecks in the production line.

Advanced conveyor systems feature adjustable speed controls, protective guides, and strategic transfer points that ensure smooth material movement between different processing stages. The integration of these components requires precise engineering to maintain optimal performance while protecting the integrity of the glass materials being processed.

Sensor and Detection Technology

At the heart of modern glass sorting systems lies sophisticated sensor technology. Multiple types of sensors work in concert to identify different glass characteristics, including color, opacity, and chemical composition. These sensors must be strategically positioned and calibrated to work effectively with existing production line components.

Integration of sensor systems involves careful consideration of environmental factors, such as lighting conditions and ambient temperature, which can affect detection accuracy. The data collected by these sensors feeds directly into the central control system, enabling real-time adjustments and quality control measures.

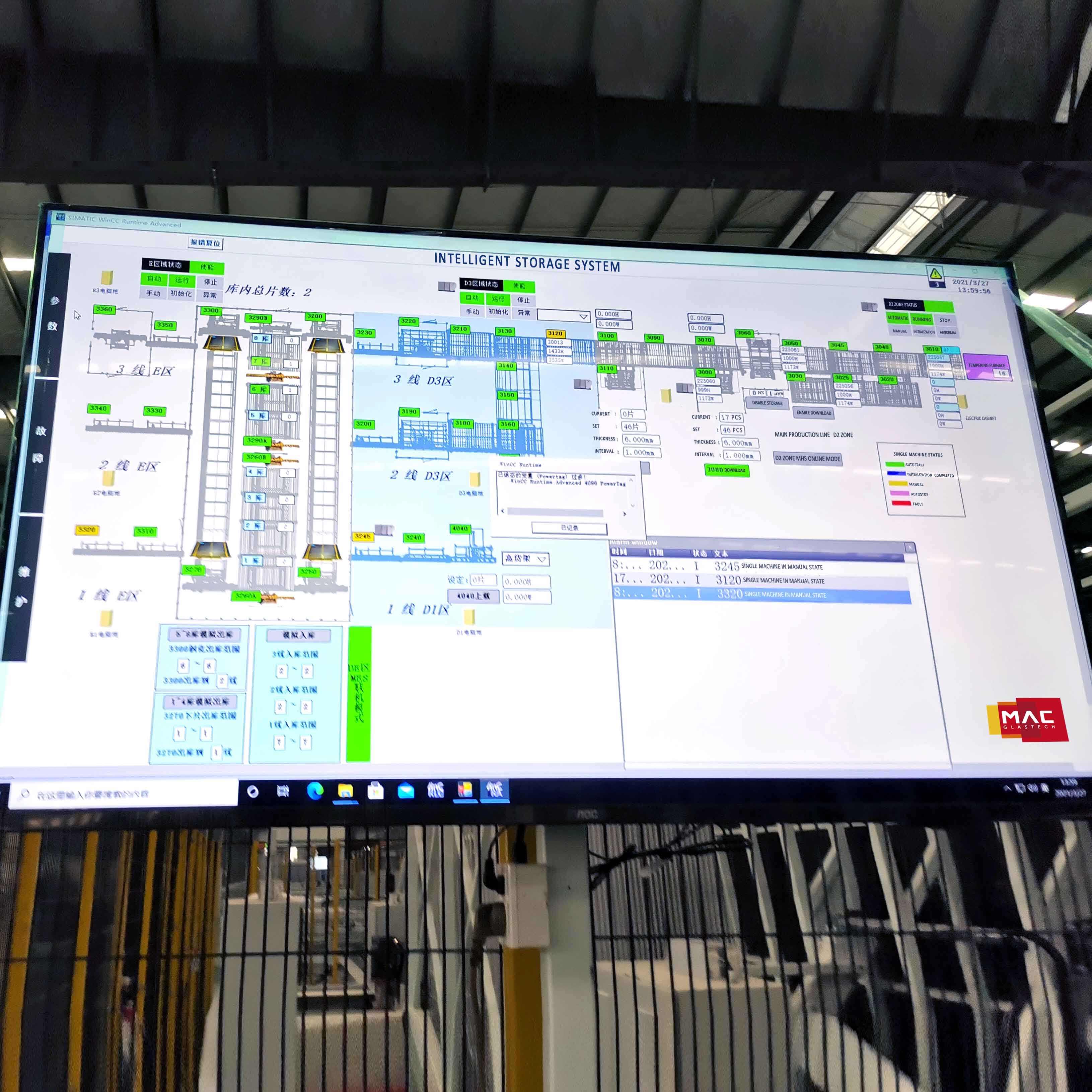

Software and Control System Integration

Central Processing Units

The integration of a glass sorting system requires sophisticated software that can communicate effectively with other automated systems in the facility. Central processing units coordinate the various components, from initial detection to final sorting actions, ensuring smooth operation across the entire production line.

Modern control systems feature advanced algorithms that can adapt to changing production requirements and maintain optimal sorting efficiency. These systems must be carefully configured to work within the existing facility's network infrastructure while maintaining the necessary processing speed for real-time operations.

Data Management and Analytics

Effective integration includes robust data management capabilities that track and analyze system performance metrics. This information is crucial for optimizing operations and maintaining quality standards across the entire glass processing line.

The analytics platform must be capable of generating detailed reports on sorting accuracy, throughput rates, and system efficiency. This data helps facility managers make informed decisions about maintenance schedules and process improvements.

Physical Integration and Space Optimization

Layout Planning and Design

Successful integration of a glass sorting system requires careful consideration of spatial requirements and existing facility layout. The system must be positioned to optimize material flow while minimizing the need for extensive modifications to existing equipment.

Facility planners must account for maintenance access points, operator stations, and safety clearances when determining the optimal placement of sorting equipment. This often involves creating detailed 3D models and flow simulations to ensure the most efficient use of available space.

Infrastructure Requirements

The physical integration of sorting systems demands appropriate infrastructure support, including electrical systems, compressed air supply, and network connectivity. These support systems must be designed to handle peak operational demands while maintaining reliability and efficiency.

Careful attention must be paid to environmental controls, including dust management and temperature regulation, to ensure optimal performance of sensitive sorting equipment. The infrastructure must also be scalable to accommodate future expansion or upgrades.

Operational Synchronization

Production Line Coordination

Successful integration requires precise coordination between the glass sorting system and other production line components. This includes synchronizing conveyor speeds, transfer points, and sorting operations to maintain consistent material flow throughout the facility.

Operators must be trained to monitor and adjust system parameters to maintain optimal performance across all integrated components. This includes understanding how changes in one area of the line can impact overall system efficiency.

Quality Control Integration

The glass sorting system must work in concert with existing quality control measures to ensure consistent product standards. This includes coordinating inspection points, implementing feedback loops, and maintaining proper documentation of quality metrics.

Integration of quality control systems often involves establishing new procedures and protocols that leverage the advanced capabilities of modern sorting equipment while maintaining compliance with industry standards.

Frequently Asked Questions

What are the power requirements for integrating a glass sorting system?

Power requirements vary depending on the system size and capabilities, but typically range from 40-100 kW for medium-sized installations. Facilities must ensure their electrical infrastructure can support both the base load and peak demands of the integrated system, including auxiliary equipment such as compressed air systems and cooling units.

How long does it typically take to fully integrate a glass sorting system?

The integration process usually takes between 4-8 weeks, depending on the complexity of the existing production line and the scope of the installation. This timeline includes physical installation, system calibration, testing, and operator training. Proper planning and preparation can help minimize disruption to ongoing operations.

What maintenance considerations should be addressed during integration?

Integration planning must account for regular maintenance access, spare parts inventory, and preventive maintenance schedules. This includes establishing clear procedures for both routine maintenance and emergency repairs, ensuring that maintenance activities can be performed without significantly impacting other production line operations.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

GA

GA

AZ

AZ