Innovations Driving the Modern Float Glass Plant

The float glass plant industry has experienced remarkable technological advancements over the past decades. Modern float glass plants are now equipped with sophisticated systems that enhance efficiency, precision, and product quality. These developments have transformed traditional manufacturing methods, enabling producers to meet growing demand while maintaining high standards.

Technological integration in a float glass plant includes automation, real-time monitoring, energy efficiency improvements, and advanced material handling. These innovations not only improve operational performance but also reduce costs and environmental impact. Understanding how these technologies are reshaping the float glass plant industry is essential for businesses aiming to remain competitive in the global market.

Automation in Float Glass Plants

Automated Production Lines

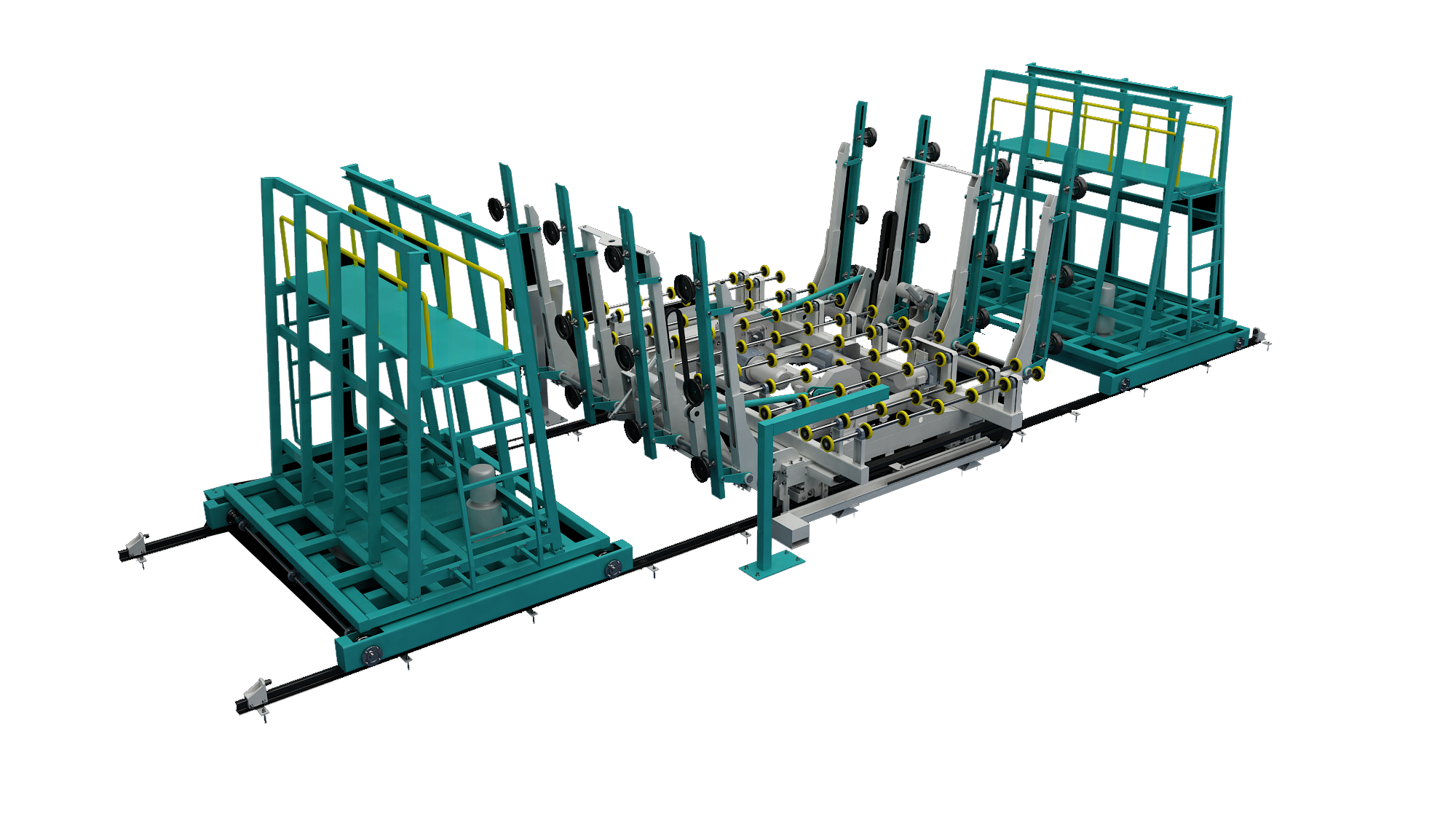

Automation is a key factor transforming float glass plants. Automated production lines reduce human intervention, minimize errors, and increase production speed. Robotics handle glass handling, cutting, and packing, which enhances safety and consistency.

Modern float glass plants utilize programmable logic controllers (PLCs) to streamline operations. These systems coordinate multiple production stages, ensuring synchronized workflows and reducing downtime.

Predictive Maintenance Systems

Predictive maintenance systems are another technological advancement in float glass plants. These systems monitor equipment in real-time, detecting potential issues before they lead to costly breakdowns.

By integrating sensors and data analytics, a float glass plant can optimize maintenance schedules, extend machinery life, and prevent unexpected downtime, ultimately improving overall productivity.

Energy Efficiency and Environmental Sustainability

Optimized Furnace Technology

The glass melting furnace is the heart of a float glass plant. Advances in furnace design, insulation, and combustion control have significantly improved energy efficiency.

Modern float glass plants implement oxygen-fuel combustion and advanced heat recovery systems, reducing fuel consumption and lowering greenhouse gas emissions. Efficient furnace technology not only decreases operating costs but also contributes to a greener production process.

Waste Reduction and Recycling

Sustainability is a growing concern in the float glass plant industry. Technological innovations facilitate the recycling of glass cullet and waste materials, minimizing environmental impact.

Automated sorting and crushing systems ensure that scrap glass is efficiently reused, lowering raw material costs and promoting sustainable manufacturing practices within the float glass plant.

Quality Control and Product Consistency

Advanced Inspection Systems

High-quality output is crucial for float glass plants, especially for applications in automotive, construction, and electronics. Modern inspection systems use optical sensors and imaging technology to detect defects, scratches, or thickness variations in real-time.

Integrating these inspection systems into the production line allows immediate correction, reducing waste and ensuring that finished products meet strict quality standards.

Precision Thickness and Coating Technologies

Precision thickness control is essential in a float glass plant to meet application-specific requirements. Technologies such as laser measurement and automated leveling systems provide consistent glass thickness across large production batches.

Additionally, coating technologies enable float glass plants to produce specialized glass with properties like low-emissivity, reflective coatings, or solar control, expanding product versatility and market potential.

Data Integration and Smart Manufacturing

IoT and Real-Time Monitoring

The Internet of Things (IoT) has become a cornerstone of modern float glass plants. Sensors placed throughout the production line collect data on temperature, pressure, and machinery performance.

Real-time monitoring through IoT platforms enables operators to make data-driven decisions, optimize production parameters, and quickly respond to any irregularities, enhancing efficiency and product quality.

Digital Twin Technology

Digital twin technology is emerging as a game-changer in float glass plant management. By creating virtual replicas of the production line, operators can simulate processes, predict outcomes, and plan maintenance more effectively.

This technology helps in troubleshooting, reducing operational risks, and continuously improving plant performance, ensuring a competitive advantage in the market.

Future Trends in Float Glass Plant Technology

Integration of AI and Machine Learning

Artificial intelligence and machine learning are expected to play a major role in the next generation of float glass plants. AI algorithms can analyze production data, predict demand, and optimize energy consumption.

Machine learning models improve defect detection, process control, and maintenance planning, enabling float glass plants to operate with greater precision and efficiency.

Flexible Manufacturing Capabilities

As market demands diversify, float glass plants are adopting flexible manufacturing systems. These systems allow rapid changes in production parameters to accommodate different glass types, sizes, and coatings without significant downtime.

Flexibility ensures that a float glass plant can meet customer requirements quickly while maintaining high productivity and quality standards.

FAQ

What technologies have the most impact on modern float glass plants?

Automation, predictive maintenance, energy-efficient furnaces, real-time monitoring, and advanced inspection systems significantly enhance production efficiency, quality, and sustainability.

How does a float glass plant reduce environmental impact?

Recycling glass cullet, optimizing furnace energy use, and implementing waste management systems help reduce raw material consumption, lower emissions, and promote sustainable manufacturing practices.

Can technology improve product quality in a float glass plant?

Yes. Advanced inspection, precision thickness control, and coating technologies ensure consistent quality and allow the production of specialized glass types for various applications.

How does IoT benefit a float glass plant?

IoT enables real-time monitoring of production parameters, predictive maintenance, and data-driven decision-making, leading to improved efficiency, reduced downtime, and higher-quality output.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

GA

GA

AZ

AZ