Modern manufacturing has undergone a revolutionary transformation with the integration of advanced grinding technologies. Among these innovations, specialized grinding equipment has become indispensable for achieving precision results in various industrial applications. The shift toward automated and semi-automated grinding solutions reflects the industry's commitment to enhanced productivity, superior quality control, and cost-effective operations across diverse production environments.

The manufacturing sector continuously seeks equipment that delivers consistent results while minimizing operational complexities. Contemporary grinding machines offer unprecedented control over material processing, enabling manufacturers to achieve tight tolerances and exceptional surface finishes that were previously difficult to attain with conventional methods. This technological advancement has particularly benefited industries requiring high-precision components, such as automotive, aerospace, and medical device manufacturing.

Understanding the specific advantages and applications of modern grinding technology helps manufacturers make informed decisions about equipment investments. The evolution from manual grinding processes to sophisticated automated systems represents a significant leap forward in production capability, offering enhanced safety features, improved operator comfort, and remarkable consistency in output quality throughout extended production runs.

Advanced Technology Integration in Modern Grinding Systems

Computer Numerical Control Implementation

Contemporary grinding machines incorporate sophisticated computer numerical control systems that revolutionize how manufacturers approach precision grinding operations. These CNC systems enable operators to program complex grinding sequences with remarkable accuracy, ensuring repeatable results across thousands of identical components. The integration of advanced sensors and feedback mechanisms allows for real-time adjustments during the grinding process, compensating for variables such as material hardness variations and tool wear patterns.

The programming flexibility offered by modern CNC grinding systems extends far beyond basic operational control. Advanced software packages enable operators to simulate grinding operations before actual production begins, identifying potential issues and optimizing grinding parameters for maximum efficiency. This capability significantly reduces setup time and minimizes material waste during initial production runs, contributing to overall cost savings and improved project timelines.

Machine learning algorithms increasingly complement traditional CNC programming, analyzing historical grinding data to suggest optimal parameters for new applications. These intelligent systems continuously improve their recommendations based on accumulated experience, helping operators achieve better results with each subsequent production run while reducing the learning curve associated with new grinding applications.

Precision Measurement and Quality Control

Modern grinding machines feature integrated measurement systems that provide continuous monitoring of dimensional accuracy throughout the grinding process. These systems utilize advanced probing technology and laser measurement devices to ensure components remain within specified tolerances, automatically adjusting grinding parameters when deviations are detected. This real-time quality control capability eliminates the need for extensive post-process inspection while maintaining the highest standards of dimensional accuracy.

The implementation of statistical process control within grinding operations enables manufacturers to track quality trends over extended periods. This data-driven approach helps identify potential equipment maintenance requirements before they impact production quality, while also providing valuable insights for continuous process improvement initiatives. Quality documentation becomes automatic, creating comprehensive records that support regulatory compliance and customer quality requirements.

Advanced grinding systems now incorporate multi-axis measurement capabilities, enabling comprehensive evaluation of complex geometries during the grinding process. This capability is particularly valuable for components with intricate surface features or multiple grinding surfaces, ensuring complete dimensional compliance without requiring multiple setup operations or separate inspection procedures.

Enhanced Productivity and Operational Efficiency

Automated Material Handling Solutions

The integration of automated material handling systems with modern grinding equipment dramatically improves production throughput while reducing labor requirements. Robotic loading and unloading systems can operate continuously, maintaining consistent cycle times and eliminating variations associated with manual handling. These systems are particularly effective for high-volume production runs where consistent handling speed and positioning accuracy are critical for maintaining overall production efficiency.

Automated storage and retrieval systems work seamlessly with grinding operations, managing work-in-process inventory and ensuring optimal workflow throughout the production facility. These systems can prioritize workpieces based on production schedules, delivery requirements, or quality considerations, optimizing the sequence of grinding operations for maximum facility utilization. The reduction in manual material handling also significantly improves workplace safety by eliminating heavy lifting and repetitive motion activities.

Advanced scheduling algorithms coordinate multiple grinding stations with material handling systems, creating synchronized production flows that minimize idle time and maximize equipment utilization. This coordination extends to maintenance scheduling, ensuring that planned maintenance activities are integrated with production schedules to minimize disruptions while maintaining optimal equipment performance throughout the production cycle.

Multi-Process Integration Capabilities

Contemporary grinding systems increasingly incorporate multiple manufacturing processes within single machine configurations, eliminating the need for multiple setups and reducing overall production time. These integrated systems might combine rough grinding, precision grinding, and finishing operations in sequential stages, maintaining workpiece positioning accuracy throughout the entire process. This integration is particularly beneficial for complex components requiring multiple surface treatments or varying finish requirements.

The ability to perform multiple grinding operations without re-fixturing workpieces significantly improves dimensional accuracy by maintaining consistent reference points throughout the manufacturing process. This approach eliminates accumulation of setup errors that can occur when components are transferred between different machines, resulting in improved overall quality and reduced scrap rates. The time savings achieved through multi-process integration often justify the increased initial investment in sophisticated grinding equipment.

Modern grinding centers feature rapid tool changing systems that enable quick transitions between different grinding operations, further enhancing productivity in mixed-production environments. These systems can automatically select appropriate grinding wheels, adjust machine parameters, and optimize coolant delivery for each specific operation, maintaining optimal grinding conditions throughout complex multi-step processes while minimizing operator intervention requirements.

Superior Quality Control and Consistency

Surface Finish Optimization

Advanced grinding technologies provide unprecedented control over surface finish characteristics, enabling manufacturers to achieve specific surface textures required for optimal component performance. Modern grinding systems utilize sophisticated spindle control and wheel dressing technologies to maintain consistent surface finish quality throughout extended production runs. The ability to precisely control grinding parameters such as wheel speed, feed rates, and coolant flow ensures repeatable surface finish results that meet stringent quality requirements.

The implementation of adaptive grinding control systems automatically adjusts grinding parameters based on real-time monitoring of surface finish development. These systems utilize acoustic emission sensors and vibration monitoring to detect changes in grinding conditions, making immediate adjustments to maintain optimal surface finish quality. This capability is particularly valuable for applications where surface finish directly impacts component performance, such as bearing surfaces or sealing interfaces.

Specialized grinding wheel technologies complement advanced machine control systems, offering enhanced performance for specific material applications. These wheels are engineered to maintain consistent cutting characteristics throughout their operational life, reducing variability in surface finish quality and extending the intervals between wheel dressing operations. The combination of advanced wheel technology and precise machine control delivers superior surface finish consistency compared to conventional grinding methods.

Dimensional Accuracy and Repeatability

Modern grinding systems achieve exceptional dimensional accuracy through the integration of thermal management systems that maintain stable machine geometry during operation. These systems monitor and compensate for thermal expansion effects that can impact grinding accuracy, ensuring consistent dimensional results throughout varying ambient conditions and extended operating periods. The ability to maintain micron-level accuracy over extended production runs represents a significant advancement in grinding technology capability.

The implementation of closed-loop feedback control systems enables grinding machines to automatically compensate for wheel wear and other variables that traditionally affected dimensional accuracy. These systems continuously monitor actual dimensions during the grinding process, making real-time adjustments to maintain specified tolerances without operator intervention. This automation significantly reduces the skill level required for achieving consistent results while improving overall production efficiency.

Statistical analysis of dimensional data collected during grinding operations provides valuable insights for process optimization and predictive maintenance planning. Modern grinding systems can identify trends in dimensional variation that may indicate developing equipment issues or opportunities for process improvement. This data-driven approach to quality management helps manufacturers maintain consistent product quality while minimizing unexpected downtime and production disruptions.

Specialized Applications and Industry Benefits

Glass Processing and Edge Finishing

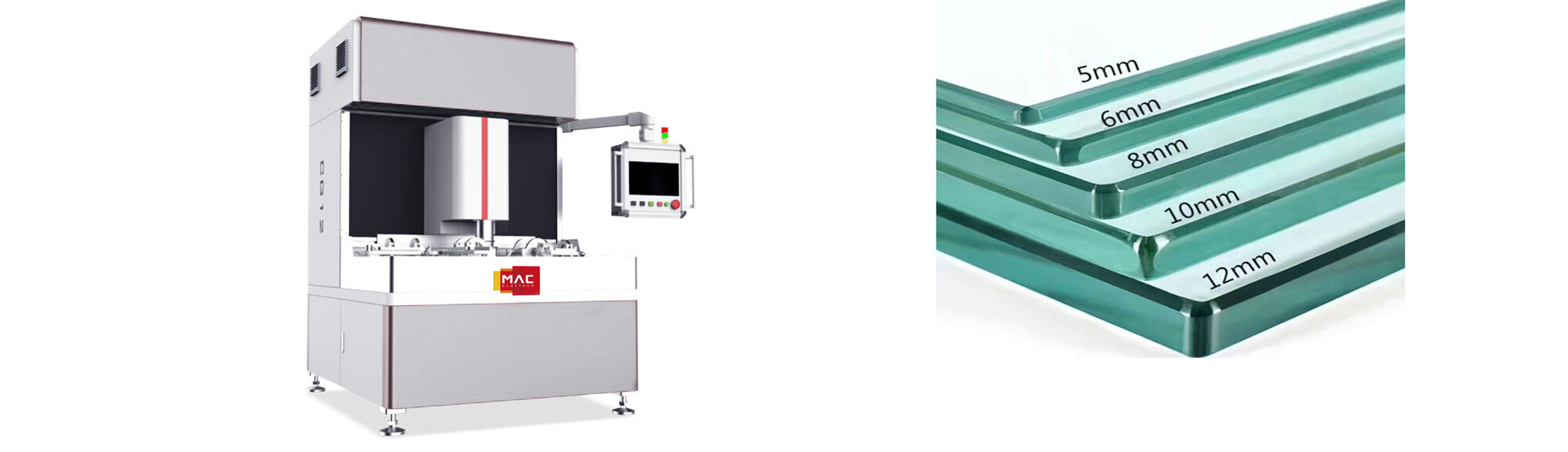

The glass manufacturing industry has particularly benefited from advances in specialized grinding technology, especially for edge processing and corner finishing applications. An offline corner grinding machine represents a significant technological advancement for glass processing facilities, offering precise control over corner radius geometry while maintaining consistent edge quality. These machines enable glass manufacturers to achieve complex corner profiles that were previously difficult or impossible to produce with conventional grinding methods.

Modern glass grinding systems incorporate specialized coolant delivery systems designed specifically for glass processing requirements. These systems provide precise temperature control and debris removal, preventing thermal stress that could cause glass breakage while maintaining optimal grinding conditions for consistent edge quality. The ability to process various glass types and thicknesses with consistent results makes these systems invaluable for architectural and automotive glass applications.

The integration of vision systems with glass grinding equipment enables automatic detection and correction of edge defects during the grinding process. These systems can identify chips, scratches, or other surface irregularities, automatically adjusting grinding parameters or triggering corrective actions to maintain product quality standards. This capability is particularly important for safety glass applications where edge quality directly impacts structural integrity and safety performance.

Automotive and Aerospace Applications

The automotive industry relies heavily on precision grinding for critical components such as engine blocks, transmission parts, and brake components. Modern grinding systems enable manufacturers to achieve the tight tolerances required for optimal performance while maintaining high production rates necessary for automotive manufacturing volumes. The ability to process hardened materials and achieve exceptional surface finish quality makes these systems essential for components subjected to high stress or wear conditions.

Aerospace applications demand even higher levels of precision and quality control, often requiring grinding operations to achieve tolerances measured in fractions of microns. Advanced grinding systems incorporate specialized fixtures and measurement systems designed specifically for aerospace components, ensuring compliance with stringent industry standards and regulatory requirements. The traceability and documentation capabilities of modern grinding systems support the comprehensive quality records required for aerospace applications.

The development of grinding technologies for advanced materials such as ceramics, composites, and superalloys has opened new possibilities for automotive and aerospace manufacturers. These materials offer superior performance characteristics but require specialized grinding approaches to achieve optimal results. Modern grinding systems incorporate adaptive control technologies that automatically adjust grinding parameters based on material characteristics, enabling effective processing of these challenging materials while maintaining consistent quality standards.

Cost-Effectiveness and Return on Investment

Reduced Labor Requirements

The automation capabilities of modern grinding systems significantly reduce direct labor requirements while improving overall production efficiency. Automated loading, processing, and unloading capabilities enable single operators to manage multiple grinding stations simultaneously, dramatically improving labor productivity compared to manual grinding operations. This reduction in labor requirements helps offset the higher initial investment in advanced grinding equipment while providing long-term cost advantages through reduced ongoing operational expenses.

The skill level required for operating modern grinding systems has decreased significantly due to advanced programming interfaces and automated process control capabilities. This reduction in required operator expertise expands the available labor pool while reducing training costs and time requirements. The ability to achieve consistent results with less specialized operators provides additional flexibility in production planning and helps manufacturers maintain consistent production levels despite workforce variations.

Modern grinding systems provide comprehensive production monitoring and reporting capabilities that enable more effective management of production resources. Real-time visibility into machine utilization, production rates, and quality metrics helps manufacturers identify opportunities for further efficiency improvements while ensuring optimal allocation of labor resources. This data-driven approach to production management contributes to ongoing cost reduction and productivity enhancement initiatives.

Material Waste Reduction

Precision control capabilities of modern grinding systems significantly reduce material waste through improved first-pass success rates and more accurate material removal control. The ability to achieve specified dimensions and surface finish requirements consistently eliminates the rework and scrap that often result from conventional grinding processes. This improvement in material utilization efficiency provides direct cost savings that contribute to rapid return on investment for advanced grinding equipment.

Advanced grinding wheel technology and automated wheel management systems extend grinding wheel life while maintaining consistent performance throughout the wheel's operational period. Automated wheel dressing and conditioning systems optimize wheel geometry and cutting characteristics, maximizing material removal efficiency while minimizing wheel consumption. These improvements in consumable utilization provide ongoing cost advantages that compound over the equipment's operational life.

The implementation of predictive maintenance programs based on machine condition monitoring reduces unexpected downtime and associated material waste from interrupted production runs. Modern grinding systems provide comprehensive diagnostic information that enables proactive maintenance scheduling, preventing equipment failures that could result in damaged workpieces or extended production interruptions. This approach to maintenance management contributes to overall cost-effectiveness while maintaining consistent production output.

FAQ

What makes CNC grinding machines more accurate than conventional grinding methods?

CNC grinding machines achieve superior accuracy through computer-controlled positioning systems that eliminate human error and maintain consistent grinding parameters throughout the process. These machines incorporate closed-loop feedback systems that continuously monitor and adjust grinding operations in real-time, compensating for variables such as wheel wear, thermal expansion, and material variations. The integration of precision measurement systems enables immediate detection and correction of dimensional deviations, ensuring components remain within specified tolerances throughout the entire production run.

How do modern grinding systems improve workplace safety compared to traditional methods?

Modern grinding systems incorporate comprehensive safety features including enclosed grinding areas, automated material handling, and advanced dust collection systems that significantly reduce operator exposure to hazards. Emergency stop systems, safety interlocks, and protective barriers prevent accidental contact with moving parts or grinding operations. Automated loading and unloading capabilities eliminate manual handling of heavy workpieces, reducing the risk of repetitive strain injuries and back problems commonly associated with traditional grinding operations.

What types of materials can be processed effectively with advanced grinding technology?

Contemporary grinding systems can effectively process a wide range of materials including hardened steels, ceramics, composites, superalloys, and specialized glass products. Advanced grinding wheel technologies and adaptive control systems automatically adjust grinding parameters based on material characteristics, enabling optimal processing of materials that were previously difficult to grind effectively. The ability to maintain consistent surface finish and dimensional accuracy across different material types makes these systems suitable for diverse manufacturing applications requiring high-quality results.

How long does it typically take to see return on investment from advanced grinding equipment?

Return on investment for advanced grinding equipment typically occurs within 18 to 36 months, depending on production volume, labor costs, and quality requirements. The combination of reduced labor requirements, improved material utilization, decreased rework and scrap rates, and enhanced production throughput contributes to rapid cost recovery. Many manufacturers also realize additional benefits through improved customer satisfaction, reduced warranty claims, and the ability to pursue higher-value applications that require superior quality and precision capabilities.

Table of Contents

- Advanced Technology Integration in Modern Grinding Systems

- Enhanced Productivity and Operational Efficiency

- Superior Quality Control and Consistency

- Specialized Applications and Industry Benefits

- Cost-Effectiveness and Return on Investment

-

FAQ

- What makes CNC grinding machines more accurate than conventional grinding methods?

- How do modern grinding systems improve workplace safety compared to traditional methods?

- What types of materials can be processed effectively with advanced grinding technology?

- How long does it typically take to see return on investment from advanced grinding equipment?

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

GA

GA

AZ

AZ