The customer's overseas call was filled with regret—due to delayed visa procedures, they ultimately missed the long-awaited factory inspection. "Please on behave of us to inspect the equipment at the factory and keep a strict check on every detail for us," the request over the phone became the entire purpose of our trip.

When we arrived at our factory, Mr. Zhou from the technical department greeted us from a distance, chuckling and teasing, "As soon as your 'equipment inspection team' arrives, we know we have to be extremely meticulous." That was indeed true. From the moment we stepped into the workshop, our "investigation" began: glancing over the neatly arranged equipment, the top priority was to verify details related to compliance—were the CE marks on key electrical components clearly visible? Were the relevant certificates complete and valid? When we noticed that the marks on some equipment were hidden inside the cabinets, Mr. Zhou wasted no time in fetching tools to open the enclosures. "Feel free to take photos; send high-definition images so the customer can see everything clearly." For some components that were not fully assembled, he simply brought over brand-new components of the same model, pointing to the certification marks on the outer packaging boxes and explaining each one in detail, fearing to miss any point that the customer might care about.

key Electrical Components with CE Marks

Energy efficiency and performance were the customer's key concerns. We squatted beside the pumps and fans, checking the energy efficiency label grades one by one to ensure each one met the highest standards required by the customer. Later, the technicians started the equipment, and amid the roar, we kept a close eye on the operating status: was the conveyor belt running smoothly without jamming? Were the silk-screening actions precise and smooth? To test the stability of the equipment, they specially prepared glass of different specifications and demonstrated the processing procedures—from washing and drilling to screen-printing—dozens of times, allowing us to observe and record every step up close.

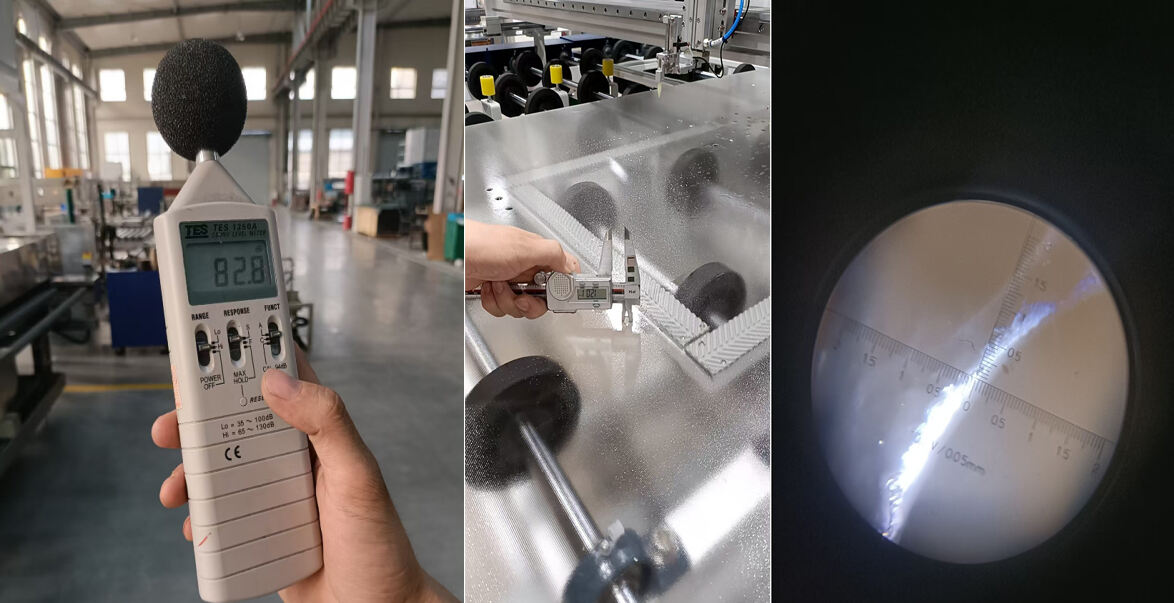

Testing tools became our "clairvoyant eyes": holding the noise detector, we saw that the readings remained within the standard range, proving that the equipment met the noise reduction requirements during operation; in front of the cleaning machine, we deliberately drew messy patterns on the glass, and only checked the box on the record sheet after watching the water flow clean the glass until it was spotless; next to the laser drilling machine, the error measured by the range finder was always within 0.1 millimeters, and under the specially made magnifying glass, the precision of the edge grinding was strictly controlled within 0.05 millimeters—behind every number was a commitment to "accuracy."

Test Details to Ensure the Quality

In addition to hardware, software details could not be overlooked. Were the bilingual (Chinese and English) equipment labels properly posted? Were the control panels in both Chinese and English? Were the translations in the instruction manuals and operation handbooks accurate? Was the list of spare parts complete? We flipped through page by page, checked item by item, to put the customer's mind at ease.

As we walked out of the workshop, the setting sun shone on the metal casings of the equipment, reflecting a warm light. We sent the folder filled with photos, videos, and inspection data to the clients, with a note attached: "All details have been confirmed, just like being here in person." A reply came quickly: "Thank you—this level of meticulousness makes us feel much more assured."

In fact, we know that the essence of inspecting goods on behalf of clients is to safeguard their expectations for the products. Those repeatedly confirmed marks, strictly measured precision, and carefully checked lists will ultimately be transformed into the client's trust—and this trust is the entire meaning behind our effort to cover every corner and leave no detail unchecked. This is exactly what our company-MAC provide to our clients and this is why we win trust and long-stable relationship from 90+ countries clients.

Copyright © 2026 China MAC GLASTECH AND AUTOMATION CO.,LIMITED. All rights reserved — Privacy Policy