The Engineering Marvel Behind Modern Glass Drilling Technology

Glass drilling machines represent the pinnacle of precision engineering in today's manufacturing landscape. These sophisticated pieces of equipment combine advanced technology with mechanical excellence to create perfect holes in one of the most delicate materials known to industry. The intricate process of drilling through glass requires not just power, but an exceptional level of control and precision that only specialized machines can deliver.

Modern glass drilling machines utilize cutting-edge features like computer-controlled positioning systems, specialized cooling mechanisms, and diamond-tipped tools to achieve unprecedented levels of accuracy. The marriage of these technologies ensures that even the most challenging glass drilling projects can be completed with minimal risk of breakage or imperfection.

Core Components of Advanced Glass Drilling Systems

Precision Control Mechanisms

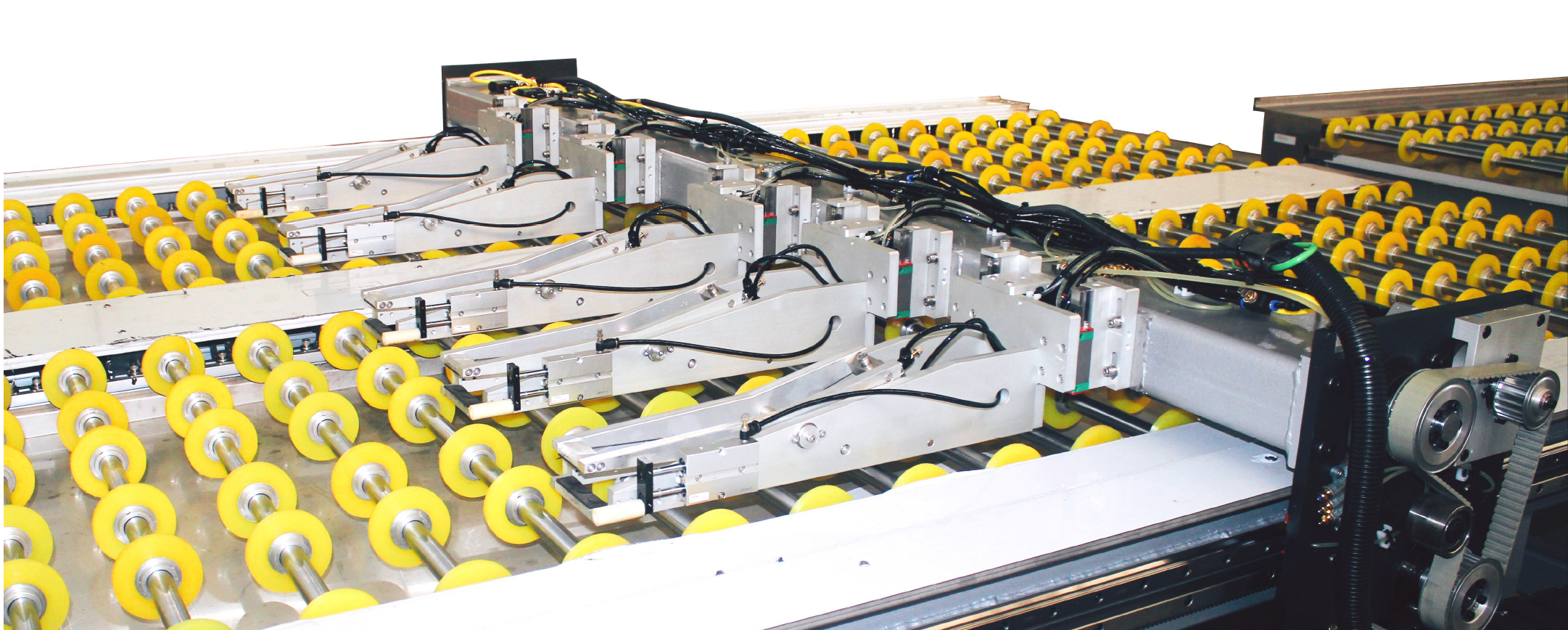

At the heart of glass drilling machines lies their sophisticated control systems. These mechanisms incorporate servo motors and advanced positioning software that can adjust drilling parameters in real-time. The precision control extends to both the vertical and horizontal movements, ensuring that each hole is perfectly aligned and executed according to specifications.

The integration of CNC technology allows glass drilling machines to maintain consistent accuracy across multiple drilling operations. This level of control is essential when working with large sheets of glass or when multiple holes need to be drilled in precise patterns.

Specialized Drilling Tools and Bits

The choice of drilling tools plays a crucial role in achieving precision results. Modern glass drilling machines employ diamond-tipped bits that are specifically designed for glass applications. These bits feature carefully engineered cutting edges that minimize the risk of chipping or cracking while maintaining optimal cutting efficiency.

The durability of these specialized tools ensures consistent performance over extended periods, contributing to the overall precision of the drilling process. Manufacturers often develop proprietary bit designs that further enhance the drilling accuracy and extend the life of both the tools and the machines.

Advanced Cooling and Lubrication Systems

Temperature Management Solutions

Effective cooling is paramount in glass drilling operations. Modern glass drilling machines incorporate sophisticated cooling systems that precisely control the temperature at the drilling point. This prevents thermal stress that could lead to cracks or other defects in the glass material.

The cooling systems in these machines often utilize a combination of water and specialized coolants, delivered through precisely calibrated nozzles. This ensures uniform cooling across the drilling area and helps maintain consistent cutting conditions throughout the operation.

Lubrication Delivery Systems

The lubrication systems in glass drilling machines are engineered to provide optimal performance while minimizing waste. These systems deliver precisely measured amounts of lubricant to reduce friction and heat generation during drilling operations. The careful balance of lubrication helps maintain tool life while ensuring the highest possible quality of finished holes.

Advanced monitoring systems continuously adjust lubrication levels based on factors such as drilling speed, depth, and material characteristics. This dynamic approach to lubrication management contributes significantly to the overall precision of the drilling process.

Quality Control and Monitoring Features

Real-time Performance Analytics

Modern glass drilling machines incorporate sophisticated monitoring systems that track every aspect of the drilling operation in real-time. These systems collect data on parameters such as spindle speed, feed rate, and drilling pressure, allowing operators to make immediate adjustments when needed.

The integration of smart sensors and monitoring equipment enables predictive maintenance capabilities, ensuring that the machines maintain their precision over time. This proactive approach to maintenance helps prevent quality issues before they can impact the finished product.

Automated Quality Verification

Quality verification systems built into glass drilling machines use advanced imaging and measurement technologies to ensure that each drilled hole meets exact specifications. These automated systems can detect even minute variations in hole diameter, depth, or position, allowing for immediate corrective action.

The combination of real-time monitoring and automated verification creates a comprehensive quality control system that maintains consistent precision across all drilling operations. This level of quality assurance is essential for meeting the demanding standards of modern glass manufacturing.

Future Innovations in Glass Drilling Technology

Artificial Intelligence Integration

The next generation of glass drilling machines is expected to incorporate artificial intelligence systems that can optimize drilling parameters automatically. These AI-driven systems will learn from historical data to predict optimal drilling conditions and adjust machine settings proactively.

Machine learning algorithms will enable these systems to identify patterns and relationships that human operators might miss, leading to even higher levels of precision and efficiency in glass drilling operations.

Advanced Materials and Tools

Research into new materials and tool designs promises to further enhance the capabilities of glass drilling machines. Developments in nanotechnology and materials science are leading to the creation of more durable and precise drilling tools that can maintain their edge longer while achieving even tighter tolerances.

These advances in tool technology, combined with improvements in machine design, will enable glass drilling machines to handle increasingly complex applications while maintaining exceptional levels of precision and accuracy.

Frequently Asked Questions

What factors influence the precision of glass drilling operations?

The precision of glass drilling operations is influenced by multiple factors including machine calibration, tool quality, cooling system efficiency, and operational parameters such as speed and feed rate. Environmental conditions and operator expertise also play significant roles in achieving optimal results.

How often should glass drilling machines be calibrated?

Professional glass drilling machines typically require calibration checks at least monthly, with full calibration services recommended quarterly or after significant maintenance work. Regular calibration ensures continued precision and prevents quality issues in the finished product.

What maintenance practices ensure consistent drilling accuracy?

Key maintenance practices include regular tool inspection and replacement, cleaning and lubrication of moving parts, calibration of control systems, and monitoring of cooling system performance. Following manufacturer-recommended maintenance schedules and using proper cleaning techniques are essential for maintaining drilling accuracy.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

GA

GA

AZ

AZ