The Complete Guide to Modern Automotive Glass Manufacturing

The automotive glass processing industry has undergone significant transformation in recent years, driven by technological advancements and evolving vehicle design requirements. As manufacturers strive to meet stringent safety standards while delivering optimal performance, selecting the right processing methods has become increasingly crucial. This comprehensive guide explores the essential considerations that influence automotive glass processing decisions and their impact on final product quality.

Processing Technology Selection

Advanced Tempering Systems

Modern automotive glass processing relies heavily on sophisticated tempering systems that ensure both strength and safety. These systems employ precise heating and cooling cycles to create glass that's up to five times stronger than standard annealed glass. The selection of tempering parameters must account for glass thickness, desired stress patterns, and final application requirements. Advanced systems now incorporate intelligent controls that automatically adjust processing variables based on glass specifications.

When evaluating tempering systems, manufacturers must consider factors such as energy efficiency, production capacity, and quality consistency. The latest tempering technologies offer improved heat distribution and faster processing times, resulting in higher throughput and reduced energy consumption. Additionally, modern systems feature enhanced cooling mechanisms that minimize optical distortions and ensure uniform strength distribution.

Lamination Process Optimization

Laminated glass production represents a critical aspect of automotive glass processing, particularly for windshields and safety glass applications. The lamination process involves bonding multiple layers of glass with intermediate layers of polyvinyl butyral (PVB) or other advanced interlayers. Selection of appropriate lamination parameters depends on factors such as glass thickness, interlayer type, and desired optical properties.

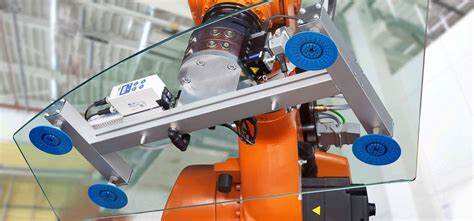

Manufacturing facilities must carefully evaluate autoclave specifications, pressure systems, and temperature controls to achieve optimal lamination results. Modern lamination technologies incorporate precision climate control and automated handling systems to ensure consistent bond strength and visual clarity. The choice of lamination equipment significantly impacts production efficiency and final product quality.

Material Considerations and Quality Control

Raw Material Selection

The foundation of successful automotive glass processing begins with proper raw material selection. Glass composition must meet specific chemical and physical requirements to ensure compatibility with chosen processing methods. Manufacturers need to consider factors such as thermal expansion coefficients, chemical durability, and optical properties when selecting base glass materials.

High-quality float glass serves as the primary input material, but its specifications must align with intended processing techniques and final application requirements. Advanced coating technologies and surface treatments may require specialized glass compositions to achieve desired performance characteristics. Material selection directly influences processing parameters and final product attributes.

Quality Monitoring Systems

Implementation of comprehensive quality control systems is essential in automotive glass processing operations. Advanced optical scanning equipment, stress measurement devices, and dimensional verification tools help ensure consistent product quality. Modern facilities employ automated inspection systems that can detect subtle defects and variations in real-time during processing.

Quality monitoring must extend throughout the entire processing chain, from raw material inspection to final product verification. Digital quality management systems help track processing parameters, maintain documentation, and facilitate quick adjustments when deviations occur. This systematic approach to quality control helps minimize waste and optimize production efficiency.

Environmental and Economic Factors

Energy Efficiency Considerations

Energy consumption represents a significant cost factor in automotive glass processing operations. Modern processing methods must balance performance requirements with energy efficiency goals. Advanced furnace designs, heat recovery systems, and improved insulation technologies help reduce energy consumption while maintaining processing quality.

Manufacturers should evaluate the long-term operational costs associated with different processing methods, including energy usage patterns and maintenance requirements. Implementation of energy management systems and monitoring tools helps optimize consumption and identify opportunities for efficiency improvements. Sustainable processing practices often lead to both environmental and economic benefits.

Cost-Benefit Analysis

Comprehensive cost-benefit analysis helps determine the most appropriate automotive glass processing methods for specific production requirements. Initial equipment investment, operational costs, maintenance expenses, and expected product yields must be carefully evaluated. Advanced processing technologies often require higher upfront investment but may offer superior long-term returns through improved efficiency and product quality.

Analysis should consider factors such as production volume requirements, market demands, and competitive positioning. The selection of processing methods must align with business objectives while maintaining necessary quality standards and meeting customer specifications. Regular review of processing costs and performance metrics helps ensure continued optimization of operations.

Frequently Asked Questions

How does glass thickness affect processing method selection?

Glass thickness significantly influences processing parameters, particularly in tempering and lamination operations. Thicker glass requires longer heating times and modified cooling cycles to achieve proper stress distribution. Processing equipment must be capable of handling the specific thickness range while maintaining quality standards and production efficiency.

What role do surface coatings play in processing requirements?

Surface coatings can affect heat absorption, processing temperatures, and overall glass behavior during manufacturing. Specialized processing parameters may be necessary to preserve coating integrity while achieving desired strength and optical properties. Coating compatibility must be considered when selecting processing methods and equipment.

How do processing methods impact final product durability?

Different processing methods create varying stress patterns and structural characteristics in the final product. Proper method selection and parameter control ensure optimal strength, impact resistance, and long-term durability. Quality control measures help verify that processed glass meets specified performance requirements for automotive applications.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

GA

GA

AZ

AZ