Laminated glass is used more and more in the high building, balustrade glass, floor, bath room glass and etc. MAC GLASTECH&AUTOMATION CO.,LIMITED can not only provide laminated glass processing solution, but also teach you how to produce high quality and standard laminated glass.

For the PVB laminated glass processing, the most important part is the press machine and Autoclave. How to choose the press machine and Autoclave to avoid the bubbles during laminated glass processing? How to produce laminated glass? Special Low-E glass, SGP and multi layer bullet proof laminated glass.

First of all, lets talk how to design and choose your laminated glass processing line special for the press machine and Autoclave. You need to consider your final products. If you produce clear float laminated glass of mass production or for architecture cutter glass, we recommend you use IR heating press machine with normal air convection which can ensure the temperature balance inside, as the IR heating is more efficiency and faster. For the Autoclave, you need have the step cooling design in the program to cool down the glass step by step, as anneal clear glass you can not make fast cooling or it will cause break of the glass, see the following picture showed:

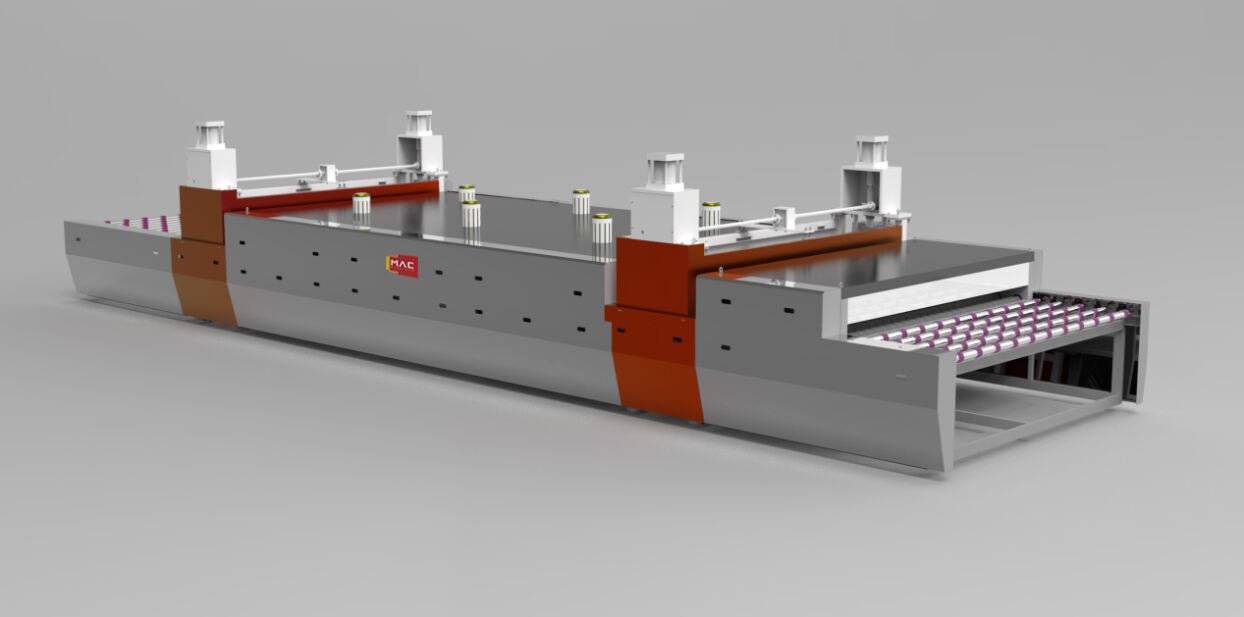

IR heating press machine

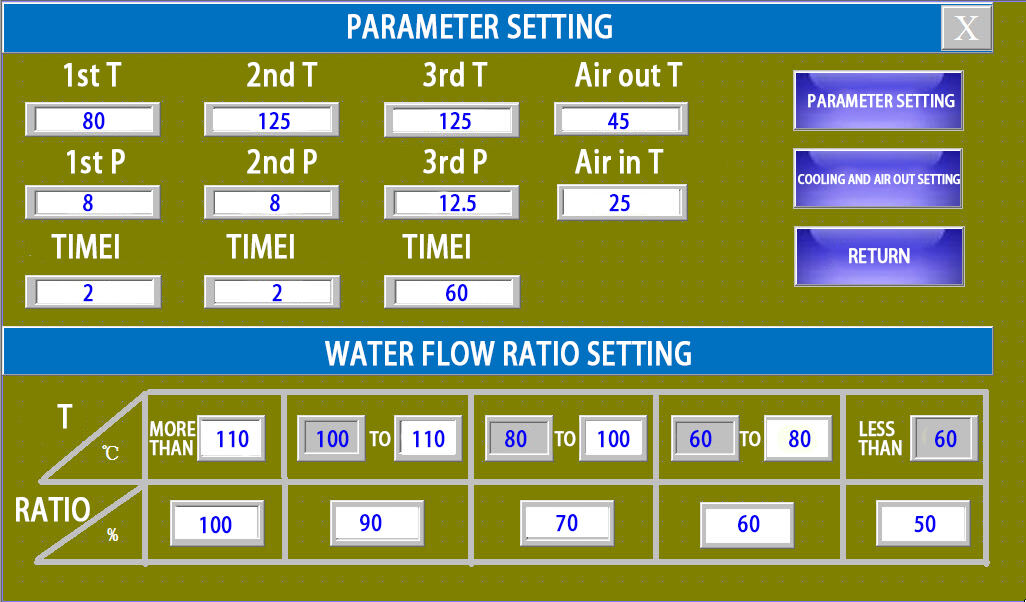

Step cooling program design in the Autoclave.

If you produce tempered LOW-E laminated glass and SGP laminated glass, we recommend you use forced air convection press machine with normal mental heaters. Compared with IR heaters, mental heater with forced air convection can control more accuracy. In this way, you can control laminated glass processing easily. Or it maybe cause a huge defect glass testing cost. And the best way is design a lower temperature and slow down the speed. MAC GLASTECH&AUTOMATION CO.,LIMITED forced air convection press machine have a good isolation with Aluminum silicate, the oven design according to tempering furnace, we can reach a lower temperature design with a little higher speed. For the Autoclave, youd better choose top air convection design with fast cooling design to ensure the clearness of the SGP laminated glass processing. See the following pictures of our design:

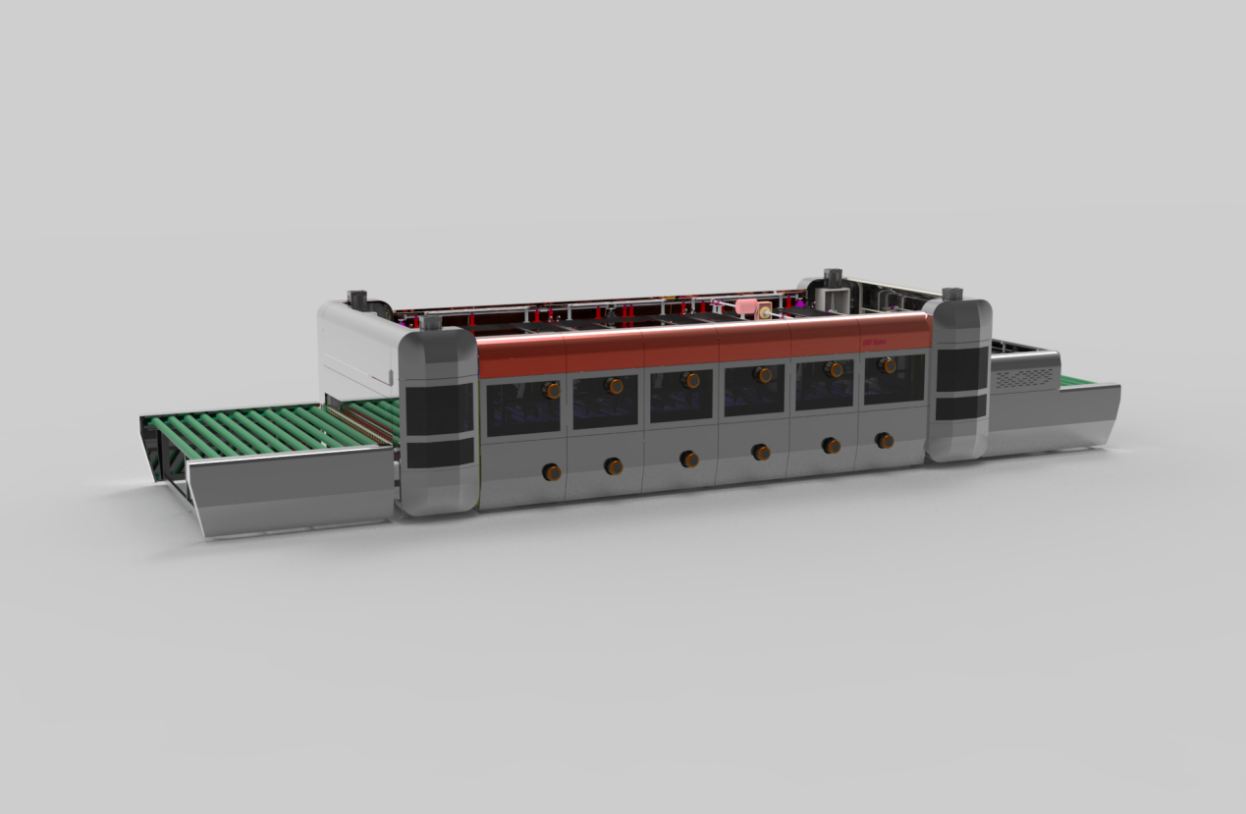

Forced air convection press machine

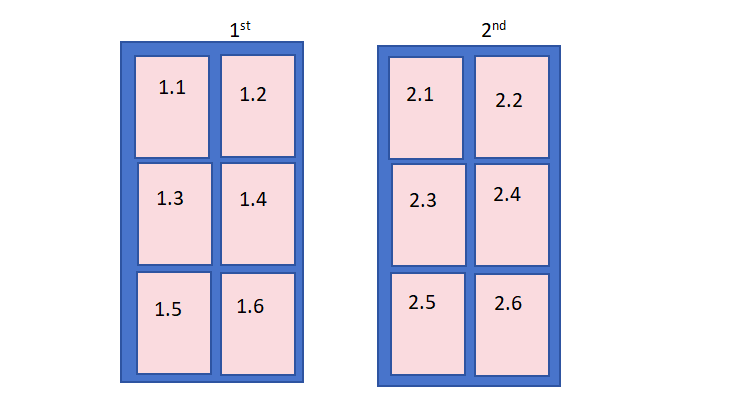

Top air convection Autoclave:

Further more, for laminated glass processing technology, we can give you following advice to improve your laminated glass processing quality:

Laminated glass processing is complicated, there are a lot details need to concern, MAC GLASTECH&AUTOMATION CO.,LIMITED give you the right solution and advice.

Copyright © 2026 China MAC GLASTECH AND AUTOMATION CO.,LIMITED. All rights reserved — Privacy Policy