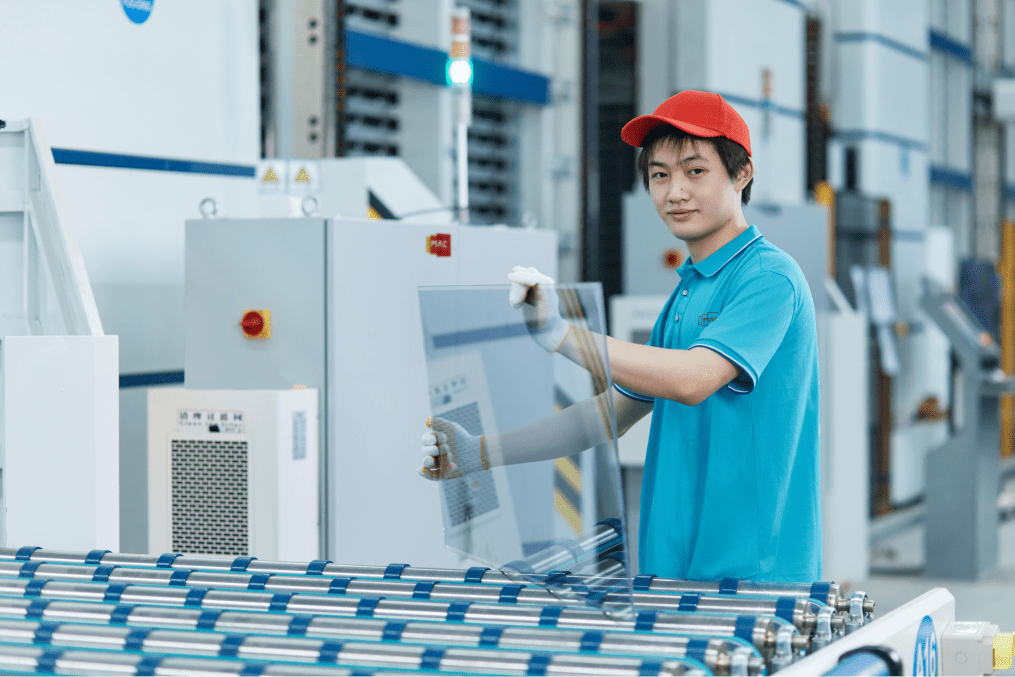

MAC-YUGONG is excited to share one more remarkable tailored intelligent glass processing project in Sichuan province in China. A group of ambitious young dreamers is building their very own "Glass Eden" – a one-of-a-kind modern glass processing plant. Capable of handling everything from oversized panels to small-size glass, the facility specializes in precision processing for premium doors and windows.

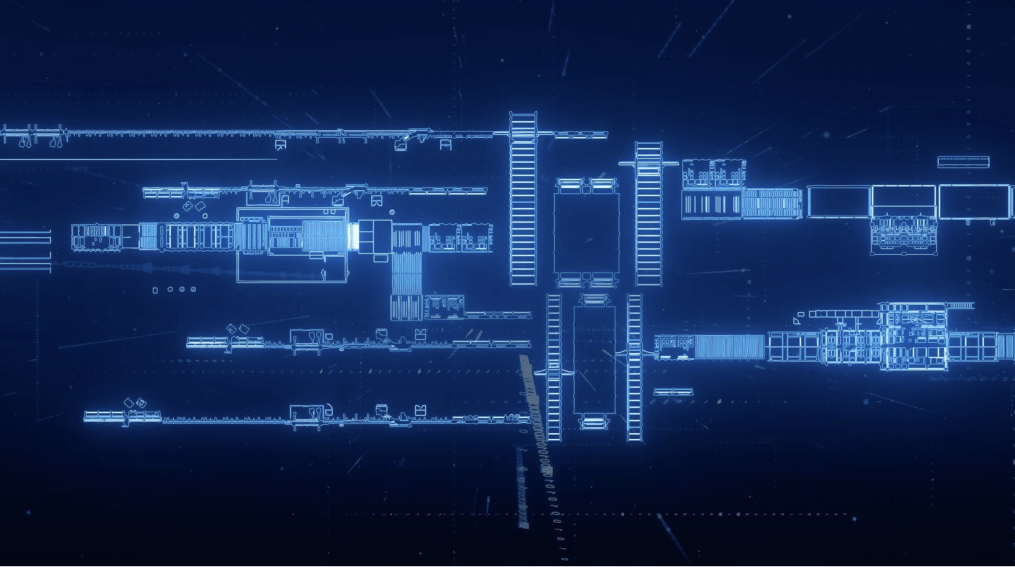

With confidence of MAC automation solution design, LIANGZHI has recently invested in not one but two automation lines. This marks a significant leap forward as it represents the most advanced and complex automation system we have ever developed.

The project is including two production lines. The first is optimized for high-end residential glass, where smaller dimensions demand exceptional precision and meticulous program design. The second line is dedicated to handling jumbo-sized glass panels of up to 3300x7000mm, ensuring superior quality and efficiency even at such large scales. Combined, these lines are designed to achieve an impressive daily tempering capacity of 6000m².

What makes this project particularly noteworthy is the challenge posed by smaller glass sizes, averaging just 0.6m². As these require more intricate programming and solution design, overcoming these complexities underscores the depth of our expertise. This achievement is not only a testament to our technical capabilities but also a defining milestone in MAC journey toward automation standards.

This line is including MAC unique design:

Raw Glass Storage System

Non workers online glass storage system connect enables automated retrieval of multi glass type based on order specification. MAC online storage system will connect with the ERP and cutting table completely without any workers operation, the system will automatically crab and transfer glass racks according to production demand.

A single raw glass storage system serves three cutting lines simultaneously, maximizing cost efficiency. One jumbo cutting line is dedicated to the Jumbo 3370 automated line, while the other two cutting lines handle small glass processing.

One Optimization Package for Two Cutting Lines

This design enables cross line raw glass pack sharing and intelligent nesting, redefining the cognitive boundaries of glass cutting.

•Double Efficiency – Two cutting line work parallelly speeds up production.

•Save Material & Costs – Unified nesting optimization maximizes glass utilization and reduces waste.

•Flexible Scheduling – Dynamic task allocation balances workload.

•Simplified Management – Centralized monitoring reduces coordination complexity.

Laser Marking Machine- Unique ID

Laser marking table, this is the beginning part for the whole line automation, it assigns a unique ID to each glass with all the glass information to maintain the downstream machine working and tracking, MAC laser marking table with a numerous program design which can read the glass information accurately and as small design as you want.

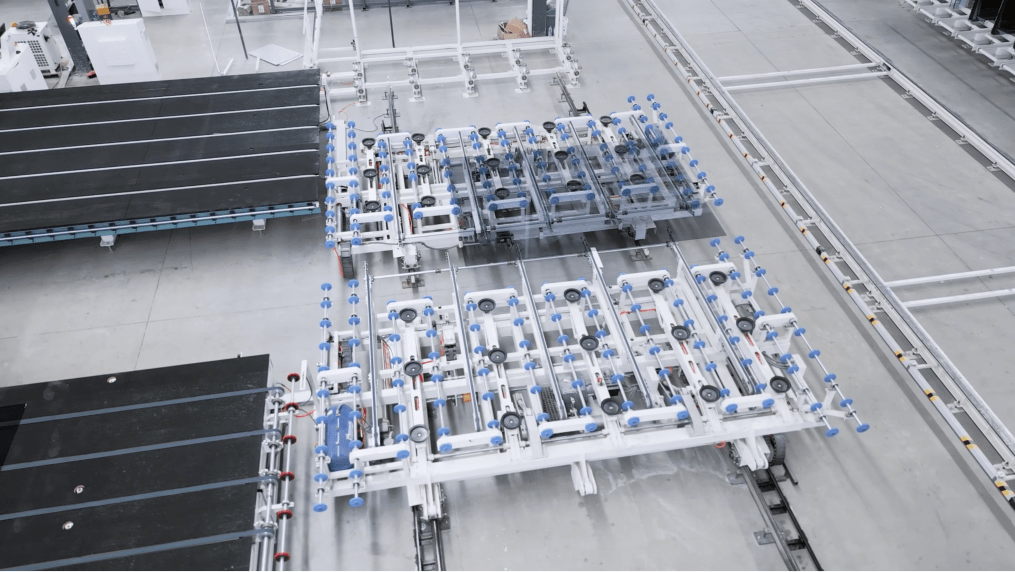

Horizontal Sorting System

Horizontal sorting system between cutting table and double edger which can coordinate the production rhythm and facilitates the optimization of edging sequence not always open the double edger tables to improve the double edger lifetime.

Pre-batching tables to organize the glass before going into the sorting system to ensure a optimal temporary storage in the sorting system.

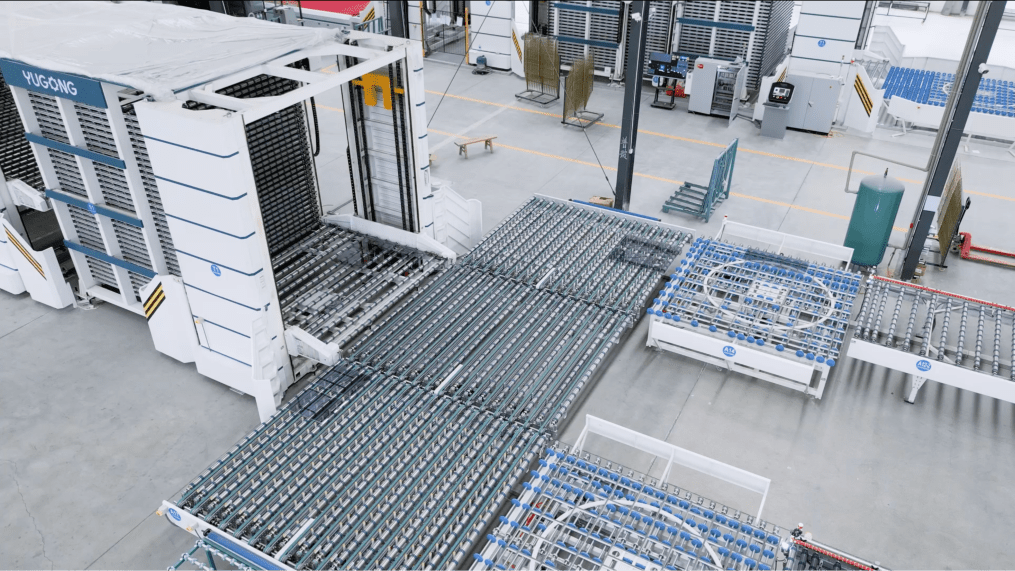

The most important part for the whole project is the horizontal sorting system in between double edger and tempering furnace:

MAC-YUGONG pioneered the industrial first design integrating three sets of horizontal sorting systems with a total of 105 layers to process massive production.

This giant sorting system includes three ladders and three storage units to achieve highly complex storage organization, precise glass sorting for the tempering furnace, efficient glass delivery to the furnace, and even oversized glass processing—all within a compact mechanical design.

MAC is the first one in China to design horizontal sorting system and pre-batching table before tempering furnace.

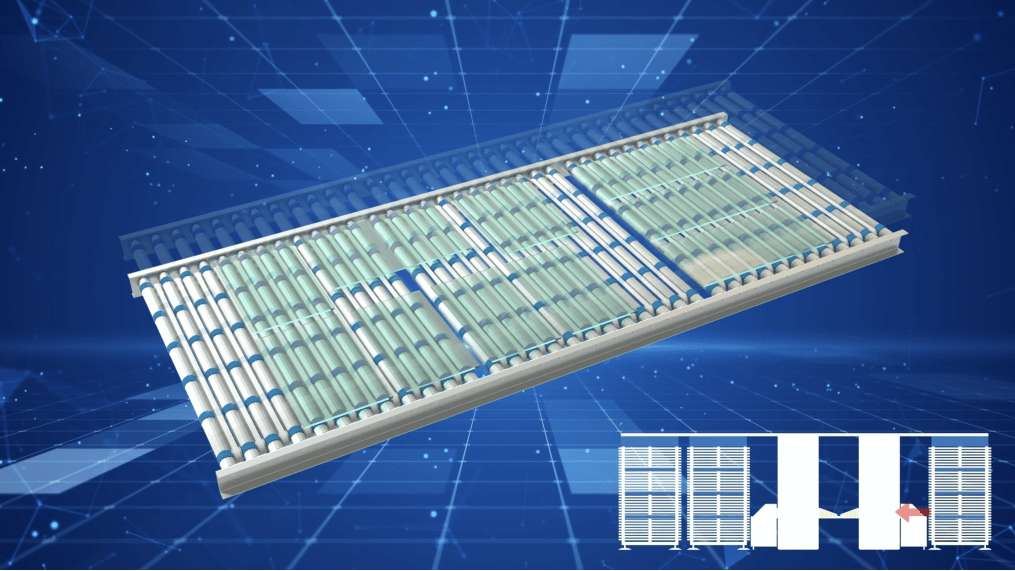

The 35 - floor horizontal storage and sorting system, designed with space-saving consideration, features a combined cloud ladder. This innovative design comprises two layers. ( technical patent No. :CN1126073908), where the upper layer functions as an inlet conveyor for glass sheets entering the storage system, and the lower layer acts as an outlet conveyor and pre-batching layer - Lower layer with XYZ three-dimensional batching can make sure reach the maximum capacity of tempering furnace.

Vertical Sorting System

The vertical sorting system connects tempering furnaces with IG/PVB lamination lines to intelligently work on pairings for IG, PVB lami, and even laminated-IG glass production.

Another highlight of this automation project is its vertical sorting system, which includes two units. Two sorting systems connect to 4 IG lines and 1 lamination line. The larger unit serves a Jumbo tempering furnace, a Jumbo IG line, a small IG line, and a PVB lamination line. The smaller unit supplies two regular IG lines and the same PVB lamination line.

Both vertical sorting systems integrate with IG and lamination lines to handle highly complex pairing logic for IG, laminated, and even laminated-IG glass combinations. Additionally, through smart mechanical and algorithmic design, the lamination lines can receive glass from both sorting systems, maximizing production flexibility and cost efficiency.

Absolutely, this is another benchmark for MAC-YUGONG in the architectural glass processing field. While young brave dreamers are just beginning their morning, MAC-YUGONG continues to redefine industry standards – persistently challenging conventional limits in glass processing technology. With each innovation, we're not just meeting expectations but reshaping the future of glass manufacturing.

MAC is the most professional smart glass processing designer not only in the mechanical but also in the program, who can lead you into glass industries 4.0. Please contact us for more future innovation.

Please click on the video link to access and view the content:https://youtu.be/dLHr_u4k4eo

Copyright © 2026 China MAC GLASTECH AND AUTOMATION CO.,LIMITED. All rights reserved — Privacy Policy